Cost Analysis of Different Thermal Barrier Materials

Thermal barrier materials play a crucial role in maintaining comfortable indoor temperatures while reducing energy consumption. Understanding the cost differences between various insulation options helps property owners make informed decisions that balance initial investment with long-term savings. This comprehensive analysis examines pricing structures, material characteristics, and performance factors across multiple insulation panel types to guide your selection process.

Selecting the right thermal barrier material involves evaluating multiple factors including thermal performance, durability, installation requirements, and budget constraints. Modern construction and renovation projects increasingly prioritize energy efficiency, making insulation panels a critical component of building envelopes. The market offers diverse options ranging from traditional materials to advanced synthetic solutions, each with distinct cost profiles and performance characteristics.

Introduction to Insulation Panels

Insulation panels are prefabricated thermal barrier products designed to reduce heat transfer between interior and exterior environments. These materials consist of insulating cores sandwiched between protective facings or available as standalone rigid boards. Manufacturing processes vary significantly depending on material composition, affecting both performance metrics and pricing structures. Common core materials include expanded polystyrene, extruded polystyrene, polyisocyanurate, mineral wool, and natural fibers. The construction industry has witnessed substantial innovation in panel technology, with manufacturers developing products that address specific climate conditions, fire safety requirements, and sustainability goals. Understanding fundamental panel characteristics helps consumers navigate the extensive product landscape and identify solutions matching their thermal performance needs and financial parameters.

Types of Insulation Panels

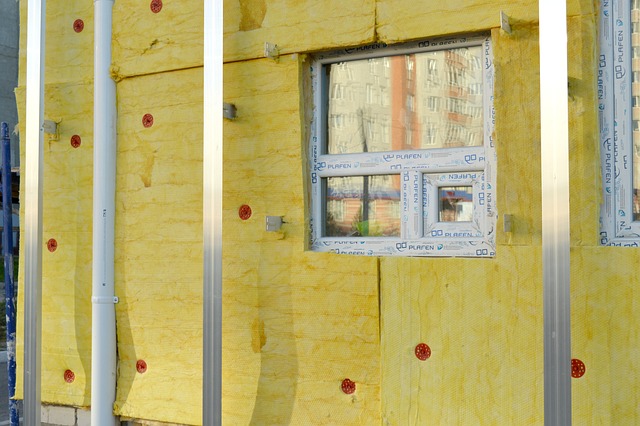

The insulation panel market encompasses several distinct categories, each engineered for specific applications and performance requirements. Expanded polystyrene panels offer lightweight solutions with moderate thermal resistance, commonly used in residential construction. Extruded polystyrene provides enhanced moisture resistance and higher compressive strength, making it suitable for below-grade applications and high-traffic areas. Polyisocyanurate panels deliver superior thermal performance per inch of thickness, often featuring reflective facings that boost energy efficiency. Mineral wool panels provide excellent fire resistance and acoustic dampening properties, frequently specified in commercial buildings and multi-family housing. Structural insulated panels combine insulation cores with structural sheathing, creating load-bearing wall systems that streamline construction processes. Natural fiber panels derived from wood, hemp, or recycled materials appeal to environmentally conscious builders seeking renewable alternatives. Each panel type exhibits unique characteristics regarding thermal conductivity, vapor permeability, dimensional stability, and environmental impact, requiring careful evaluation against project-specific criteria.

Insulation Panel Uses and Benefits

Insulation panels serve multiple functions across residential, commercial, and industrial construction sectors. Wall assemblies benefit from continuous insulation layers that minimize thermal bridging through structural framing members. Roof systems incorporate rigid insulation boards to prevent heat loss during winter months and reduce cooling loads during summer periods. Foundation walls and basement applications utilize moisture-resistant panels that maintain thermal performance in below-grade environments. Refrigerated storage facilities and cold chain logistics operations depend on high-performance panels to maintain precise temperature control. Beyond thermal regulation, insulation panels contribute to moisture management by controlling condensation risks within building assemblies. Acoustic benefits emerge from panels with sound-absorbing properties, improving occupant comfort in noise-sensitive environments. Energy cost reductions represent the most compelling financial benefit, with properly insulated buildings consuming substantially less heating and cooling energy compared to uninsulated structures. Additional advantages include reduced HVAC equipment sizing requirements, improved indoor air quality through better envelope control, and enhanced property values resulting from superior energy performance ratings.

Insulation Panels Costs

Pricing for insulation panels varies considerably based on material composition, thickness, facing options, and regional market conditions. Understanding cost structures enables accurate project budgeting and value comparisons across product categories. Material costs typically range from basic to premium pricing tiers, with installation labor adding significant expense depending on application complexity and site accessibility.

| Material Type | Typical Cost Range (per square foot) | Key Cost Factors |

|---|---|---|

| Expanded Polystyrene | $0.40 - $1.20 | Density, thickness, facing type |

| Extruded Polystyrene | $0.80 - $2.00 | R-value, edge profile, color additives |

| Polyisocyanurate | $1.00 - $2.50 | Facing material, thermal performance |

| Mineral Wool | $1.20 - $3.00 | Fire rating, density, acoustic properties |

| Structural Insulated Panels | $6.00 - $12.00 | Panel size, core material, structural capacity |

| Natural Fiber Panels | $1.50 - $3.50 | Material source, certifications, availability |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Installation costs depend on application method, with mechanical fastening systems generally proving less expensive than adhesive applications requiring surface preparation and specialized equipment. Labor rates fluctuate based on geographic location, contractor experience, and project scale, with larger installations often qualifying for volume discounts. Additional expenses may include vapor barriers, fasteners, adhesives, and protective coatings required for specific applications. Transportation costs impact overall project budgets, particularly for bulky low-density materials requiring significant shipping volumes. Waste factors typically add 5-15 percent to material quantities, accounting for cutting losses and damaged pieces during handling.

Pros and Cons of Insulation Panels

Insulation panels offer numerous advantages that make them attractive for diverse construction applications. High thermal efficiency per inch of thickness allows space-efficient designs that maximize usable floor area while achieving target energy performance. Rigid panel formats facilitate rapid installation compared to loose-fill or batt insulation products, reducing labor costs and construction schedules. Moisture resistance in closed-cell foam products prevents water absorption that would compromise thermal performance. Dimensional stability ensures panels maintain their shape and effectiveness throughout building lifecycles without settling or compression. Many panel products provide structural benefits, contributing to wall rigidity and racking resistance.

However, several limitations warrant consideration during product selection. Higher material costs compared to traditional batt insulation may strain project budgets, particularly for price-sensitive applications. Some foam-based panels release harmful gases during fire exposure, necessitating protective barriers in occupied spaces. Installation precision becomes critical, as gaps between panels create thermal bridges that undermine overall system performance. Certain materials require specialized cutting tools and safety equipment, increasing installation complexity. Environmental concerns surround foam products manufactured with blowing agents that contribute to global warming potential. Disposal challenges arise at end-of-life, with limited recycling infrastructure for many panel types. Vapor impermeability in some products requires careful moisture management strategies to prevent condensation issues within wall assemblies.

Conclusion

Evaluating thermal barrier materials requires balancing initial costs against long-term performance benefits and operational savings. The diverse range of insulation panel products enables tailored solutions for virtually any construction scenario, from basic residential projects to specialized industrial applications. Material selection should account for climate conditions, building codes, moisture management requirements, and sustainability objectives alongside budget constraints. While premium products command higher upfront investments, superior thermal performance often justifies additional expense through reduced energy consumption over building lifetimes. Consulting with building science professionals and experienced contractors ensures optimal product selection and proper installation techniques that maximize insulation system effectiveness.