Shifting Paradigms: Unearthing The Hidden Potential of Industrial Co-Bots

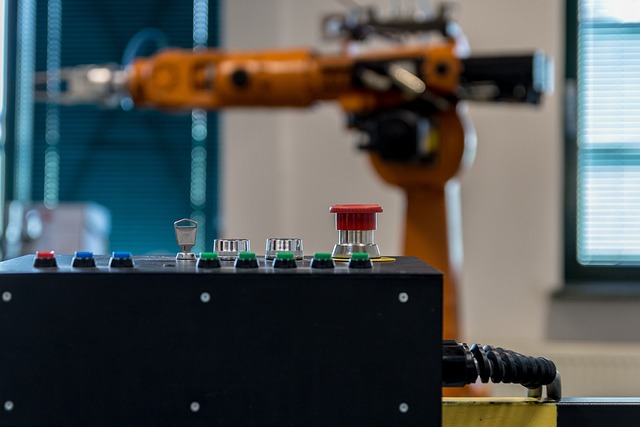

Introduction: In the quest for a more streamlined, efficient industrial environment, an unexpected ally is gaining prominence - collaborative robots or 'co-bots'. These intelligent machines are rewriting the rules of automation, fostering symbiotic relationships with human workers, and unlocking significant potential.

Industrial Co-Bots: A Brief History

The concept of robots working alongside humans isn’t new. The term ‘co-bot’ was first coined in the 1990s by researchers at Northwestern University. However, it was not until the early 2000s that advancements in sensor and AI technology allowed for the development of co-bots that could safely interact with human workers.

In the last decade, these machines have evolved from simple, single-task devices to complex, multi-function systems capable of learning and adapting to a wide range of tasks. They have found applications across numerous industries, from manufacturing and logistics to healthcare and hospitality.

The Rise of the Co-Bot: Current Trends and Insights

The global market for co-bots is expected to grow exponentially over the next few years. This rise is fueled by several factors, including the increasing demand for automation, a growing need for flexible manufacturing solutions, and the rising labor costs.

Co-bots offer numerous advantages over traditional industrial robots. They are safer, more flexible, easier to program, and can perform a wider range of tasks. In addition, their ability to work alongside humans can boost productivity and efficiency, while also reducing the risk of workplace injuries.

The Impact of Co-Bots: Benefits and Challenges

The potential benefits of co-bots are enormous. They can handle repetitive, mundane tasks, freeing up human workers to focus on more complex and rewarding tasks. They can also operate in environments that are hazardous for humans, increasing safety and reducing the risk of injury.

However, there are also challenges associated with the integration of co-bots into the industrial workspace. These include technical issues related to programming and maintenance, as well as concerns about job displacement and the need for worker retraining.

Co-Bots in Action: Real-World Applications

Co-bots are already making a difference in a variety of industries. In the automotive sector, they are being used to assemble complex components, reducing production time and increasing precision. In the healthcare sector, they are assisting with delicate surgical procedures, enhancing precision and improving patient outcomes.

Insights for Practical Application

- Consider the tasks that could be automated: Co-bots are best suited for repetitive, mundane tasks that do not require human judgment or creativity.

- Evaluate safety measures: Ensure that adequate safety protocols are in place to prevent accidents and injuries.

- Invest in worker training: Employees must be trained to work alongside co-bots and to take on new roles as required.

- Stay updated: Technology is evolving rapidly, and it is important to stay abreast of the latest developments in co-bot technology.

Conclusion

The rise of co-bots represents a significant shift in the industrial landscape. These intelligent machines offer numerous benefits, from increased productivity and efficiency to improved safety and job satisfaction. However, their integration into the workspace also presents challenges that must be addressed. By adopting a strategic, well-informed approach, businesses can harness the potential of co-bots and navigate the transition to a more automated, efficient, and collaborative industrial future.